Metallurgical

Metallurgical Testing typically uses microscopy to provide important information about the structure and properties of metal and alloy samples. These services are also called Metallography Evaluation, Metallographic Examination and Metallurgical Analysis.

As metals are subjected to melting, cooling and working processes, their grains and crystalline structures change. The metallography experts at BCTS study the material’s microstructure and/or macrostructure to evaluate the effects on material properties.

The engineers in BCTS’s metallurgical laboratory perform various types of microstructure and macrostructure examinations, corrosion analysis and micro hardness testing. BCTS can evaluate defects, determine structural features, identify alloys, evaluate the effects of heat treatments, and ensure that materials conform to required specifications. Root cause failure analysis services are also provided when performance issues occur with metal products.

The metallurgical testing services at LTI are accredited and performed in accordance with ASTM and other industry specifications. Detailed internal procedures are also observed to ensure efficient order processing and the reliability of test results.

Customers receive a Certified Test Report showing the complete results of each metallography test.

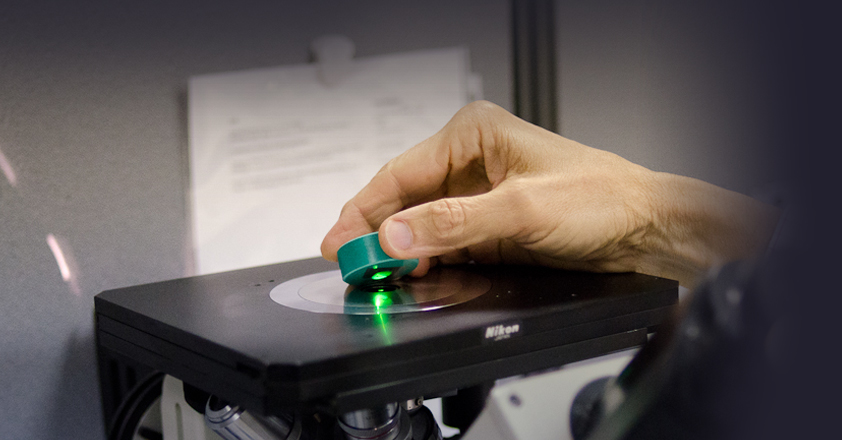

The first step in metallurgical analysis is sample preparation. Samples are prepared in our metallurgical lab using precision cutting, mounting, grinding and polishing techniques, as well as etching when required.